5 Gallon Cap Plastic Injection Mould

Brand :Focare

Product origin :China

Delivery time :60 days

Supply capacity :500 molds per year

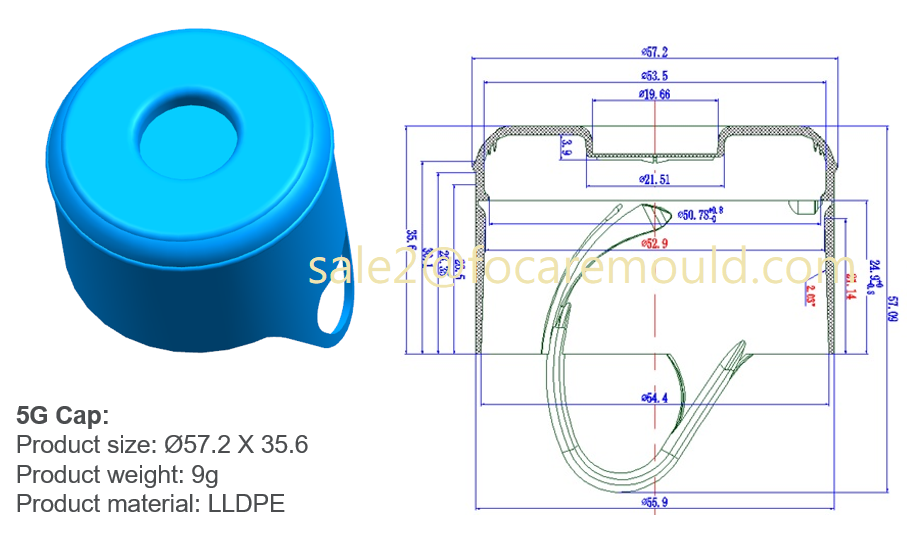

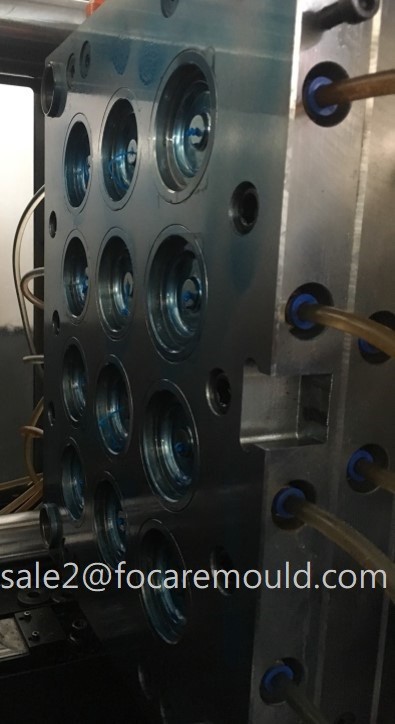

The plastic raw material of 5G cap is LLDPE, which has high gloss, high heat resistance and better fluidity than the general materials. In addition, the steel of mold core and cavity is S136, with a hardness of 48-52, which can better for mold life. It could be design with 12 cavities or 16 cavities, each cavity has its own independent cooling system to ensure that the products can be better shaped and cooled.

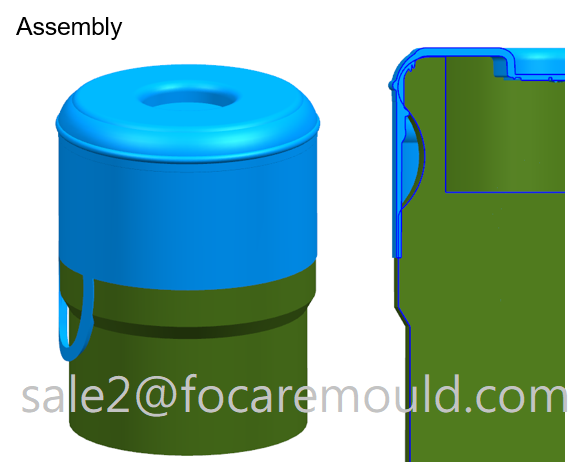

The bottle cap is used to seal the bottle. According to different functions, the bottle cap has different shapes and design ideas. I believe that everyone has drunk 5 gallons of bottled water in the office. Do you know how to make 5 gallons of bottled cap?

The plastic raw material of 5G cap is LLDPE, which has high gloss, high heat resistance and better fluidity than the general materials. In addition, the steel of mold core and cavity is S136, with a hardness of 48-52, which can better for mold life. It could be design with 12 cavities or 16 cavities, each cavity has its own independent cooling system to ensure that the products can be better shaped and cooled. In addition, the raw materials can flow better, so, cycle time. Greatly reduced.

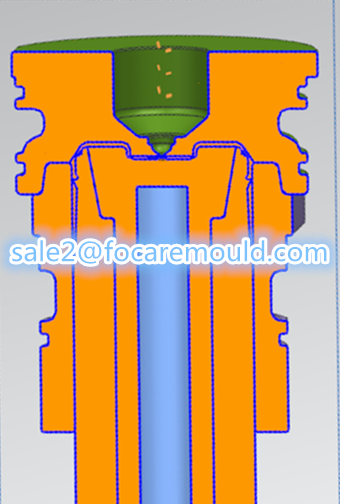

In design, there are two best design features of this mould.

1. Every cavity has a separate independent clamping mould function.

2. Two-time ejection, the two layers of ejector plates are topped together, topped to a certain distance, the upper layer is stopped, and the thimble plate below continues to go up to the product, because the 5 gallon bucket has under-cut, so it cannot be ejected at one-time, otherwise the product will be damaged.

Focare Mould is an experienced two-color injection mold maker; we have our own design group, skilled mold workers and technical mold testing workers. Even though you don’t have any experience in two-color injection molding area, just give us your ideal, we can design the products, make the molds and train your workers to operate the injection molding machine for you.