Application of (Becu) beryllium copper in plastic mould

Beryllium copper is often used in plastic injection molds due to its unique combination of properties that make it well-suited for this application.

Some of the key advantages of using beryllium copper in plastic injection molds include:

1. High Thermal Conductivity:

Beryllium copper has high thermal conductivity, which helps in cooling the molten plastic quickly, reducing cycle times and improving productivity.

2. High Hardness and Wear Resistance:

Beryllium copper is harder than many other mold materials, which makes it resistant to wear and deformation, leading to longer mold life and improved part quality.

3. Corrosion Resistance:

Beryllium copper is resistant to corrosion, which is important when working with corrosive plastics or in environments where moisture is present.

4. Dimensional Stability:

Beryllium copper has good dimensional stability, meaning that it maintains its shape and size well under repeated heating and cooling cycles.

5. Conductivity:

While not as conductive as steel, beryllium copper is still sufficiently conductive to allow for efficient cooling of the mold.

For example,

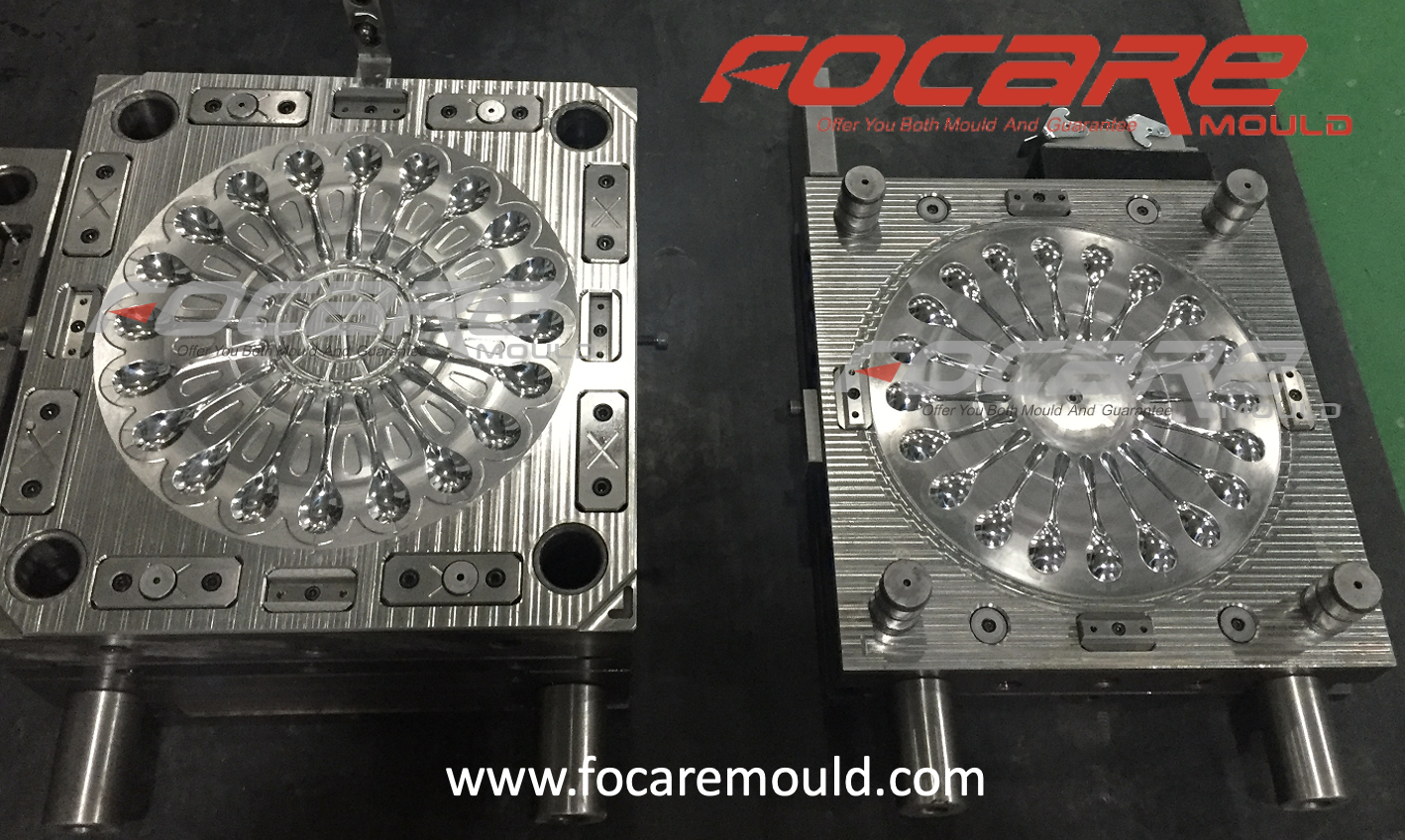

Because disposable cutlery (spoon/ fork/ knife) is used only once, its characteristic is cheapness. To meet the requirement of cheapness, we must consider the production cost. First of all, the cutlery must be light, which means that the raw materials it needs are not much.

In addition, the finished products are arranged in a circular shape on the mold, which can save more steel.

To save the production time, the mold needs very good cooling system to shorten the cycle time; we also use BeCu in the center to have better cooling.

Overall, the combination of these properties makes beryllium copper a popular choice for plastic injection molds, particularly in applications where high precision, high productivity, and long mold life are required.

Focare Mould experts in manufacturing plastic molds with BeCu.

If you have any new mould plans, welcome to contact us to further discussion.